J-Bolts

J-Bolts

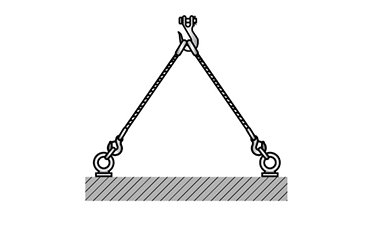

J-bolts are a type of hook anchor fastener that are typically embedded into concrete foundations on construction sites. The top of the bolt is threaded so it can accept other threaded fasteners, and the bottom is hooked in a "J" shape to anchor onto rebar or other structural components in the concrete.

When installed, the hooked end of the bolt is submerged and cast in place while the threaded end protrudes above the concrete. Once the concrete has set, walls or other fixtures can be secured to the concrete base by threading a nut and washer onto the exposed bolt.

Application Considerations

J-bolts are commonly used to secure beams, equipment, columns, and similar components into concrete. Additionally, they can be used to anchor things like signage, posts, and light fixtures with the hooked end. With those functions in mind, there are several key points to consider before choosing the correct bolt for your application.

- Building Regulations and Codes: Codes and regulations specify guidelines for different elements in a construction setting like embedment depths, load capacities, and spacing. It's important to comply with these guidelines, which may influence the size or material of your bolt.

- Load Requirements: The j-bolt will support the application's load, which will be influenced by weight, potential movement or vibration, and other similar factors. Ensure your bolt is capable of supporting the load the application will exert on the anchor.

- Environmental Elements: In situations where the bolt will be exposed to the elements, think about what those elements will be; water, heat damage, temperature fluctuations, chemical materials, dirt and debris, or other elements may corrode the bolt if it isn't made from corrosion-resistant material.

These considerations will help you narrow down the correct j-bolt for your application.

Benefits

J-bolts offer several benefits for use in construction applications:

- Simple Installation: J-bolt installation is a fairly simple process compared to other anchoring techniques.

- Adjustable: J-bolts can be removed and replaced without disturbing much of the surrounding concrete, which allows for adjusting within the application. The threaded end also allows for mating components to be attached and detached with ease.

- Standard Components: Construction applications often require standardized fasteners and components. J-bolts are widely used fasteners that, when used properly and adhere to required specifications, commonly comply with codes and regulations.

What Is the Difference Between a J-Bolt and an Anchor Bolt?

The difference between a j-bolt and an anchor bolt is specificity; a j-bolt is a type of anchor bolt. Another common type of anchor bolt is an

L-bolt, which features a 90° angled end - like an "L" - instead of the hooked "J" end.

J-Bolt Sizes and Material

Huyett offers two j-bolt options, each in alloy steel material.

- This j-bolt comes with a zinc finish and features a 1/4 in. thread diameter and 20 threads/in., with an inside height of 2-5/16 in.

- This j-bolt comes with a zinc finish and features a 1/2 in. thread diameter and 13 threads/in., with a shank length of 6-1/2 in.