Spring Hose Clamps

Spring Hose Clamps

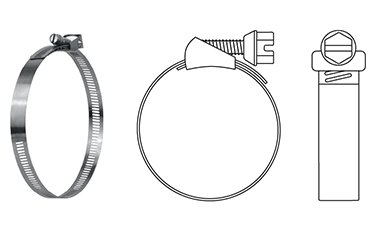

Spring hose clamps feature a unique design with an open metal circle that is not fully closed. The open ends are connected through tabs that, when squeezed together, use spring tension to expand the clamp. The clamp is then placed onto the tube or hose and the tabs are released to apply tension and compression to the application. These clamps are ideal for applications where the hose diameter fluctuates due to changes in pressure.

Application Considerations

When using spring hose clamps, consider the following application factors to ensure optimal performance and reliability:

- Hose Material: Automotive hoses may be made from a variety of materials, but whatever it is will have to resist extreme heat and chemical corrosion. Evaluate the type of hose material in your application and assess whether the spring clamp material can support the required corrosion resistance without damaging the hose.

- Hose Pressure: Since spring clamps are well suited for hose applications with fluctuating pressure, it's important to know how much the outside diameter of the hose (hose O.D.) will change in use. Make sure the clamp can adjust accordingly without restricting or releasing the required hose pressure.

- Application Environment: Consider how the application environment may put stress, wear, and tear on your spring hose clamp. The hose and clamp will likely be exposed to extreme temperatures, chemicals, dirt and damaging debris, and other corrosive elements. The clamp is available in spring steel with phosphate, Doriflake, and zinc finishing options - evaluate which finish will help minimalize the damage to the components.

Benefits

There are several key benefits of using spring hose clamps into your hose applications:

- Constant Tension: These clamps maintain 360° constant spring tension pressure on hose fittings, accommodating temperature fluctuations and ensuring a secure seal on appropriately sized hoses.

- Wide Band: The clamp's wide band distributes even pressure over the mating surface; this helps minimalize damage that narrow bands cause by digging into the hose while also reducing the risk of bottlenecking the hose pressure.

- Easy Installation: While specialty tools are required, the right pliers will simply squeeze open, grip the clamp tabs to open the circle, and release once the clamp is in place.

- Reusable: Spring hose clamps are reusable as long as they are maintained, making them a cost-effective investment over time.

Product Line

Huyett offers spring hose clamps through our

Rotor Clip product line. This line also offers a wide range of high-quality retaining rings in a variety of styles, including

snap rings,

housing rings,

spiral rings, and more.

Spring Hose Clamps vs. Wire Hose Clamps

Wire hose clamps are similar to spring hose clamps because they use spring tension to compress the mating hose and will expand or contract with low pressure changes. However, the main difference is the clamp is made from narrow spring wire, which reduces the band's surface coverage.

Wire clamps are better suited for applications where the hose will not be damaged by a thinner profile. They work well in applications with hard-to-reach areas, are competitively priced, and are reusable. However, if you require your clamp to provide even distribution and support higher pressure fluctuations, spring clamps are the more reliable option.

How Do I Choose the Right Spring Hose Clamp Size?

Selecting the correct spring hose clamp size is crucial for a proper fit and seal. The clamp should have a snug fit without digging into the hose.

Measure the hose O.D. (outside diameter) and consider how much it will contract or expand in use. Then, refer to the clamp I.D. (inside diameter) and see if its minimum and maximum I.D. will accomodate the hose diameter.