Wire Hose Clamps

What Are Wire Hose Clamps?

Wire hose clamps are spring steel hose clamps made from round wire to provide constant tension on hose fittings. With a thinner profile than its wide band spring clamp counterpart, wire clamps are most suitable for low-pressure applications. They work well in hard-to-reach locations and are often used on vacuum lines in automotive applications.

Application Considerations

To ensure optimal performance in your application, there are a few factors to consider when using wire hose clamps:

- Hose Size: If the hose is the same size or smaller than the clamp, the clamp will not be able to exert spring force onto the hose to keep it in place. If the hose is significantly bigger, the clamp may put too much pressure on it, which could restrict the fluid movement too much or cause damage to the hose. Check the clamp's inside diameter maximum and minimum range on Huyett's product detail page to see if it is compatible with your hose.

- Movement: If your application will experience any motion or vibration, it's important to evaluate if the clamp will stay in place. Unwanted movement may cause damaging friction against the hose or could dislodge the clamp.

- Temperature: While it's good to evaluate all environmental elements in your application, temperature is especially important with fluid. Consider whether changing temperatures will impact the hose pressure and if you will need to account for that with your hose and the clamping strength.

- General Environment: You should also consider whether the hose and clamp will be exposed to weather, sunlight, dirt and debris, or external fluids. All of these could damage the application without proper protection. Wire clamps are available in carbon steel spring wire, spring steel, and spring wire with plain or a variety of zinc finishes to help combat corrosion.

Benefits

Wire hose clamps are ideal for low-pressure applications with limited mobility and simple installation requirements. They offer a variety of benefits for these scenarios. They are:

- Versatility: The clamp's simple design allows it to easily adapt to different applications, as long as the hose supports its thin profile.

- Easy Installation: To install a wire hose clamp, simply squeeze the two metal tabs together to widen the circle before connecting to the hose. This can be done will common household tools.

- Adaptable Size: Since the clamp does not lock into place, the circle expands and contracts with the hose to adjust to pressure changes.

- Cost Efficient: Huyett offers these reusable fasteners at competitive prices, so your upfront investment quickly pays for itself.

Product Line

Huyett offers wire hose clamps through our

Rotor Clip product line. This line also offers a wide range of high-quality retaining rings in a variety of styles, including

snap rings,

housing rings,

spiral rings, and more.

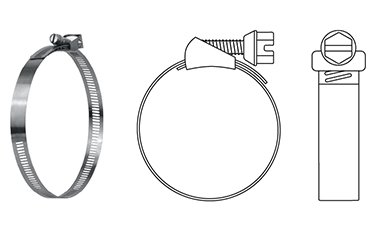

Single and Double Wire Styles

There are a few subtypes of wire clamps. They include:

- Double Wire: These clamps feature two wire circles wound closely together, with the metal tabs interlocked at the top.

- Single Wire: Single wire clamps feature one wound circle with tabs bent up at either end. This is also available as single wire slim .

Difference Between Wire and Spring Hose Clamps

Wire and spring clamps are similar in functionality, but they are different enough to warrant an explanation.

Wire clamps

feature a single or a double looped wire that open when its metal tabs are squeezed to open the circle and are released to apply spring tension to the hose.

Spring clamps operate much the same way with metal tabs and spring tension, but the metal is flat and provides a wider surface area to distribute the load more evenly. The main downside is that wire clamps require special installation and removal tools.

What Are the Different Types of Hose Clamps?

Metal clamps are available in a wide variety of styles. Some of the most popular include

worm gear (which feature a perforated adjustable band that is locked in place with a worm gear screw),

t-bolt (a type of quick release clamp with a smooth band),

ear clamps (featuring two protruding metal steps that crimp together to tighten the clamp), and more.

To get an in-depth look at these and other popular styles, check out our

Hose Clamp Types and Features guide.