Lifting & Rigging Hardware

Lifting and Rigging Hardware for Industrial Use

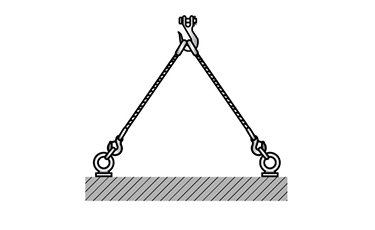

Rigging and lifting hardware represents a group of components that are essential in construction, transportation, agriculture, and many other industries. These fasteners hoist, tow, anchor, suspend, and lift other components to safely secure and move objects. Typically, these components are used in conjunction with each other to form a rigging or lifting assembly; for example, wire ropes may be reinforced with a wire rope thimble and clamps to form an eye that can be connected to a turnbuckle assembly or eye bolt for anchoring or suspension. It is vital to ensure these components are compatible with each other, meet all relevant regulations, do not attempt to perform tasks outside of their designated function, and operate within the appropriate working load limits.

Application Considerations

It is especially important to consider application requirements when working with lifting and rigging hardware. Here are some general factors to evaluate before using these components.

- Safety and Regulations: Lifting and rigging applications pose a significant safety risk to users, as they typically involve suspending large loads overhead. Always consult the fastener's manufacturing guide and any relevant regulations to ensure you are following proper safety guidance.

- Overhead Rating: Ensure you only use components that are specifically rated for overhead lifting to perform these lifts.

- Working Load Limits: Regardless of the type of part in use, do not exceed its Working Load Limit (WLL), also known as the Rated Capacity (RC). This limit, which should be provided by the manufacturer, communicates how much load weight the part can safely support; note whether this limit will change based on the lifting or rigging angle of the load.

- Qualified Operators: Many lifts and rigs require a qualified specialist to safely assemble, operate, and disassemble lifting and rigging equipment/machinery. Check whether this requirement applies to your operation.

- Angled Lifts: If you will be lifting loads, evaluate whether it will be a straight lift, an angled lift, or a free-swinging lift. This will impact the type of hardware you choose and the WLL of the hardware (WLL diminishes with angled loads, so ensure you are calculating it with the angle in mind).

- Fastener Compatibility: Always evaluate how your fasteners will work with each other and if they will support each other's WLLs. You should also consider if the materials and finishes will corrode, slip, or deform when used together and if the connection points are designed to attach to each other.

- Environment: Will the application be exposed to harsh weather conditions? Extreme temperatures? Corrosive elements like dirt and debris, moisture, or chemicals? These factors will help you evaluate the appropriate material and finish for your fasteners.

Benefits

There are many individual benefits provided by each unique type of hardware. As a whole, these components offer:

- Versatility: With a wide variety of connecting components that support both light and heavy loads, you can configure a custom assembly that is tailor made for your application with Huyett’s product line.

- Durability: Since this hardware is meant to support a wide range of loads in construction applications, it is manufactured with durable materials and finishes that allow it to withstand harsh environments and challenging lifts or rigs.

- Reusability: Many (not all) lifting and rigging components are reusable, provided they are well taken care of and pass inspections. This makes parts like turnbuckles, chains, eye bolts, clevis and yoke ends, lifting eye nuts, hooks, shackles, and swivels all cost-efficient investments for long-term use.

Product Line

Huyett is proud to offer our Aztec Premium Lifting and Rigging Hardware line, which offers an extensive catalog of parts and components to support rigging and lifting needs.

Types of Rigging and Lifting Hardware

Huyett offers a wide selection of rigging hardware comes in different forms:

- Chain: Includes Grade 30 proof coil and Grade 70 transport

- Chain Hardware: Includes cold shuts, double clevises, quick links, repair lap links, rigging master links, and spring snap hooks

- Turnbuckles: Includes combinations of eye, hook, jaw, stub, hook, and stub ends; and turnbuckle bodies and bolt pins

- Hooks: Includes grab hooks and slip hooks

- Wire Rope Hardware: Includes fist grip clamps, swage sleeve fittings, welded rings, wire rope clamps, and wire rope thimbles

- Clevis and Yoke Ends

- Rod Ends

Lifting hardware is a slightly different category and includes parts that are suitable for lifting (although you should always check the manufacturer's manual to confirm this and ensure proper usage). These parts include:

- Eye Bolts: Includes plain pattern, shoulder pattern, and wire eye bolts

- Lifting Eye Nuts: Includes heavy-duty and standard eye nuts

- Shackles: Includes chain and anchor shackles

- Swivels: Includes eye-eye, jaw-eye, and hoist-ring swivels.

What is the Difference Between Rigging and Lifting?

The difference between rigging and lifting hardware is that all of these components may be used for

rigging

(suspending, tying, towing, and supporting loads), but only some of them are designated as safe for

lifting

.

Rigging involves the process of setting up equipment to safely move heavy objects, utilizing ropes, cables, and pulleys. Lifting, on the other hand, refers to the actual action of raising or moving those heavy objects upwards or to a different location. Both are critical in construction, manufacturing, and logistics, requiring specialized knowledge and equipment to ensure the safety and efficiency of operations. Rigging sets the stage safe lifting, making them complementary processes.