Cotter Pins

What Is A Cotter Pin?

Cotter pins are a diverse product at Huyett and come in a wide range of shapes, offering unique connection options to lock pin fasteners and components in place. Also known as split pins, cotter split pins, and cotter keys, they are a steel-formed pin inserted into a drilled hole of a clevis pin, shaft, or other assemblies to lock the mating fastener in place. It is called a split pin because it features two prongs that are pulled apart after insertion.

Most cotter pin installations are simple, quick processes that usually only requires simple tools like pliers. Simply insert the split end into a pre-drilled hole, clasp the extended prong with a pair of pliers, and bend it backwards until it wraps around the mating fastener. Bend the shorter prong back in a similar manner - this will lock the cotter key in place.

This installation works for

standard cotter pins or other types with similar designs – like

hammerlock cotter pins - which encompasses most styles. Other types, like

bow-tie cotter pins, are just as simple to install but do not require bending to lock in place.

Application Considerations

As with all fasteners, it is important to consider what environment your cotter pin will be in; this will help you determine which material, finish, shape, and size to choose when selecting a pin. Think about the following environmental elements:

- Humidity or precipitation - will your pin need to resist natural erosion?

- Chemical or lubrication exposure - will your pin need to resist chemical erosion?

You will also need to consider the physical demands of the application:

- Force/movement/pressure - will your pin need to withstand repeated hits? Compression? Friction?

- Durability - how long will the pin need to function and hold up within the application?

Most of your cotter pin's functionality will depend on its material and finish. Huyett offers different types of cotter pins in a variety of materials including stainless steel, spring wire, carbon steel with a plain finish or a zinc clear finish. Standard cotter pins are offered in even more materials like aluminum, brass, and Monel with galvanized, passivated, zinc yellow, black, and cadmium finishes.

To learn more about how different types of metals offer different benefits, read our

Key Stock Material Selection Guide. Additionally, our

Types of Metal Finishes for Fasteners Guide explains how different types of finishes work and what they have to offer.

Benefits

There are several benefits to using a cotter pin, especially if you are looking for a cost-effective fastener that does not need to be permanent. Here are a few ways that these pins provide simple, economical fastening solutions:

- Cost Efficiency: It is a low-cost fastening option compared to other fastening pins, especially if you do not need to reuse the part. When they are used to keep nuts in place on bolts, they increase the value of the application by providing a more secure connection.

- Ease of Use: There are no special tools or techniques required to install a cotter pin - simply insert the prongs into the mating hole and bend them back to lock them in position with any standard set of pliers.

- Range of Options: Huyett offers cotter pins in up to 10 different styles with a wide range of materials and finishes to accommodate different environments, accessibility points, strength thresholds, and other application requirements.

- Vibration or Loosening Reduction: It provides a perpendicular, secure barrier that cannot vibrate out of place, which is a risk with fasteners that are screwed into place.

How Do You Use A Cotter Pin?

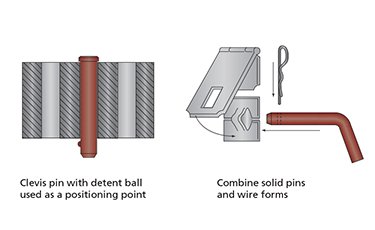

A cotter pin is typically used to fasten nuts onto bolts, secure axles on vehicles or machinery, or to keep hitch pins or clevis pins in place.

In some instances, you may need to drill the mating hole to install the pin, but this is the only instance in which an extra tool is required. To remove it, simply bend or cut the prongs until you can pull the top half of the pin out of the mating hole.

Cotter Pin Types

Huyett offers 10 different types of cotter pins, available in low MOQs with 24-hour shipping:

- Bow Tie: Allows for installation from either side

- Circle: Well suited for lighter duty applications like fabrics or rubber

- Clinch: Features a self-locking design for added security

- Hammerlock: Popular in automotive applications to hold wheel bearings in place

- Humped: Features separated prongs for easy installation

- Ring: Loop design offers extra security

- Self-Locking: Features a secondary bump below the head to press prongs outwards

- Standard: Popular, versatile style with straight prongs for easy installation

- T-Head: Ideal for applications when limited clearance is required

- Wedgefast: Features an integrated clasp that spreads the prongs during installation for applications with limited access

How To Measure a Cotter Pin

A cotter pin features two essential measurements: the diameter and the effective length. To learn how to take these measurements, watch our instructional video below: