Washers

Washers: Enhance Fastening Efficiency and Reliability

Washers are an industrial fastener and machine component commonly used to distribute load, reduce surface damage, and prevent unwanted movement in conjunction with another fastener, like a nut and bolt. Available in various styles, sizes, and materials, washers play a critical role in ensuring the effectiveness and longevity of industrial fastening applications. Each type serves a specific function and caters to diverse needs across industries.

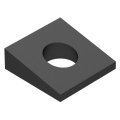

Washers are typically thin discs with a central hole to accommodate mating threaded fasteners. They are usually placed between a nut or bolt head and the surface being fastened. Although many types of washers are flat, there are several varieties (including ogee washers, beveled washers, spring washers, and others) that have a raised or textured surface. These serve specific purposes; for example, beveled washers feature one raised edge to form a slant down to the low edge to accommodate angled surfaces in construction projects. Washers serve several key purposes, including:

- Load Distribution: By distributing the load over a larger surface area, washers help prevent the connection point from giving way under too much concentrated pressure.

- Surface Protection: Washers act as a barrier between the fastener and the surface to reduce friction, prevent corrosion, and prevent damage to delicate materials.

- Enhanced Functionality: Some types of washers, like load indicating or bonded sealing washers, provide specific functional benefits like tension control or air-tight protection against leaks.

- Specialized Applications: Washers come in a variety of designs to suit specific applications, such as structural washers for heavy-duty construction or finishing washers for aesthetic purposes.

Huyett currently offers the following types of washers:

- Flat Washers: This encompasses a range of styles, including dock, fender, flat, and square washers

- Finishing Washers: These washers are used with countersunk screws to provide a neat and finished appearance

- Structural and Indicating Washers: This category includes washers that help facilitate exact tension and washers that are suitable in heavy-duty scenarios

- Ogee Washers: The curved design helps distribute loads and protect wood surfaces from mating fasteners

- SAE Washers: These flat, circular washers conform to SAE standards

- USS Washers: The oversized design is especially useful when load distribution is important

- Lock Washers: Lock washers are available in different styles that all provide extra locking mechanisms for enhanced security

- Spring Washers: The spring design provides deflection properties that provide additional tension and reduce vibrational loosening