- Huyett Marketing Department

- 05/26/2022

When discussing nut and bolt sizes, it is not only important to understand the differences between inch and metric fasteners, but to also understand which measurements are essential to determining the sizes of the nuts and bolts you need for your applications.

All sizes of nuts and bolts fall into one of two main categories:

standard/inch

and

metric

. While it may seem natural to look for imperial nut and bolt sizes when searching for fasteners measured in inches, the industry does not use this term. Instead, you will find

standard, inch, or U.S.

fasteners. Fortunately,

metric

is the only industry term for fasteners measured in millimeters.

Differences Between Inch and Metric Nuts and Bolts

While the functionality and physical characteristics of inch and metric

nuts and

bolts are essentially the same, how they are sized is different. The sizes are communicated by key measurements, standards, and strength grade markings.

The biggest difference between nut and bolt inch and metric sizes is how measurements are defined. While each type of nut or bolt will have its own set of characteristics to measure, every fastener is measured by its

thread diameter

and

threads per inch (TPI)

or

thread pitch

.

Thread Measurements

Regardless of inch or metric measurements, thread diameter is defined by either the outside diameter (OD) or the inside diameter (ID) of the part:

Outside Diameter (OD) or Major Diameter

- Nuts: the distance between the roots of the threads

- Bolts: the distance between the crests of the threads

Inside Diameter (ID) or Minor Diameter

- Nuts: the distance between the crests of the threads

- Bolts: the distance between the roots of the threads

The OD is more commonly used in basic measurements.

The thread measurement depends on the measurement system in use:

- Threads Per Inch (TPI): used to measure inch fasteners — how many threads are present in an inch of the thread length

- Thread Pitch: used to measure metric fasteners — the distance between two thread crests, given in millimeters

Measurement Format for Size Names

Nut and bolt size names, regardless of the measurement system, are always given as the

OD followed by the TPI or thread pitch

. The names within each measurement system will look slightly different.

Inch Format

The measurement of an inch nut or bolt will be listed as the

thread size

— a number between one and 12 or an inch increment followed by the threads per inch (TPI). If the diameter is less than 1/4 inch, the diameter will be listed as a number between zero and 12; the larger the number, the closer it is to 1/4 inch. When the diameter is equal to or larger than 1/4 inch, it will be listed as an inch increment.

Thread Size

| OD

|

|---|---|

#10 - 32

| 0.19"

|

#12 - 24

| 0.216"

|

1/4" - 20

| 0.25"

|

5/16" - 18

| 0.3125"

|

The TPI, or number of threads within an inch of the thread length, will immediately follow the diameter.

Example 1:

#6-24 (#6 = 0.138 in. OD; 24 = 24 threads in one inch of thread length)

Example 2:

1/4"-28 (1/4 = 1/4 in. OD; 28 = 28 threads in one inch of thread length)

Metric Format

The thread size of a metric nut or bolt is listed as the letter "M" followed by a number that indicates the number of millimeters across the diameter and then the thread pitch.

Example:

M4 x 0.7 (M4 = 4 mm OD; 0.7 = 0.7 mm between thread crests)

Coarse and Fine Threads

Nut and bolt size names will sometimes also factor in whether the thread is coarse or fine. Simply put, coarse threads are thicker and farther apart from each other, while fine threads are thinner and closer together.

There are a few acronymns that are used to designate each thread type:

Standard Coarse Threads

- UNC: Unified National Coarse threads comparable to ISO metric threads

- UNRC: Unified National Coarse threads; the "R" indicates "rolled" external threads that have a rounded root contour. They are full interchangeable with UNC fasteners.

- UNJC: Unified National Coarse threads with an increased minor diameter and controlled root radius that disperses tensile strength over a broader area. Derived from a military specification (MIL-S-8879), they are designed for high stress applications. However, they are not interchangeable with other UNC fasteners.

Metric Coarse Threads

- ISO metric threads will simply use the word "coarse."

Standard Fine Threads

- UNF: Unified National Fine threads.

- UNRF: Unified National Fine threads; the "R" indicates "rolled" external threads that have a rounded root contour. They are fully interchangeable with other UNF fasteners.

- UNJF: Unified National Fine threads with an increased minor diameter and controlled root radius that disperses tensile stress over a broader area. Derived from a military specification (MIL-S-8879), they are designed for high stress applications. However, they are not interchangeable with other UNF fasteners.

Metric Fine Threads

- ISO metric threads will simply use the words "fine" or "super fine."

Sometimes, you will see the same thread size listed twice, each with a different thread pitch or TPI next to them. For example:

- M2.3 x 0.45 vs. M2.3 x 0.4: These have the same diameter, but the thread pitch in the first measurement is larger than the second one, so the distance between threads will be bigger.

- #10 - 24 vs. #10 - 32: These have the same diameter, but the TPI in the first measurement is lower than the second one, so there will be fewer threads per inch of thread length.

Because TPIs and thread pitches are calculated differently, remember the following:

- Inch Threads: A higher TPI indicates finer threads as there are more threads within an inch of thread length.

- Metric Threads: A lower thread pitch indicates finer threads as there is less space between each thread crest.

Standards

Nuts and bolts are regulated by

standards, depending on their measurement system.

Inch Standards

As our

Guide to Nuts and Bolts explains, most inch nuts and bolts comply with the Unified Thread Standard (UTS). The American Society of Mechanical Engineers (ASME) and The American National Standards Institute (ANSI) regulate this standard. Additionally, the Society of Automotive Engineers (SAE International) regulates standards for parts used in automotive applications. If any of the following standards apply to your nuts or bolts, you are working with inch fasteners:

- UTS: Unified Thread Standard for screw threads commonly used in the U.S. and Canada including Unified National Coarse (UNC) and Unified National Fine (UNF) threads. ASME/ANSI — Specifies screw thread properties for three classes of general purpose unified screw threads including: UN, UNR, and UNJ series fasteners.

- SAE: A standard that designates the number of threads per inch for coarse and fine American (or standard) bolts, screws, pipes, ports, and flange ports.

Metric Standards

For metric nuts and bolts, the most common standards are:

- ISO: Strict specifications for coarse, fine, and superfine metric threads defined by the International Organization for Standardization.

- DIN: Standards defined by the German Institute for Standardization (or Deutsches Institut für Normung, hence "DIN") for thread styles commonly used in Europe.

ASTM

The American Society for Testing and Materials (ASTM) standard covers both inch and metric nuts and bolts. We'll discuss how to identify the appropriate measurement system in the following section.

Strength Grade Markings

Sometimes, manufacturers mark their nuts and bolts with indentations to indicate the strength of the fastener. Different standards use different strength markings, but there are a few markings you are most likely to encounter.

Inch Grade Markings

Inch nuts regulated by the SAE will have lengthwise lines within the circle on the top of the nut, while bolts will have lines on the bolt head moving from the center of the head outwards.

Metric Grade Markings

If a nut or bolt shows numbers instead of line indentations to indicate their strength grade, it is a metric fastener. However, depending on the fastener's standard, metric nuts can also show a pattern of lines and dots between the circle and the sides of the nuts. Metric nuts will print these indentations outside the circle.

ASTM Grade Markings

You may also come across bolts with alphanumeric marks, typically an "A," "B," or "F" in combination with one to four numbers. This mark could exist on its own or along with lines. This is an ASTM strength grade mark. If this mark is followed by a capital "M," that signifies that the fastener is metric. If there is no "M" present, it is an inch fastener.

Manufacturers are not required to mark their fasteners with strength grades, so this is not a guaranteed method of identifying the inch or metric designation of your fastener. Many nuts and bolts will only imprint the manufacturer's brand mark, which may be a simple letter and should not be confused with a strength grade.

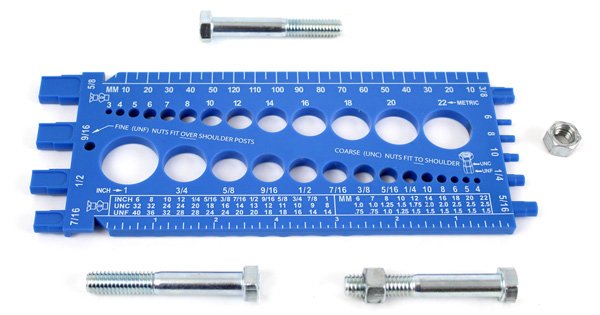

How to Identify Your Nut and Bolt Measurements

There are times you will need to identify the measurements of your nuts and bolts from scratch. There is no exact way to do this without specific tools, but you can narrow down the key measurements with a basic inch and metric ruler. From here, you can take your fasteners to a local hardware store and locate the closest match.

To identify the nut and bolt measurements:

- First, determine if you are working with inch or standard fasteners by identifying the standard associated with your nut or bolt or by looking at the bolt head or the top of the screw. If there are visible markings, refer to the previous descriptions.

- If you are unable to determine the measurement system, you'll need to record the OD in both inches and millimeters.

- OD in Inches and Millimeters

- Measure an inch of the thread length and count the number of threads within the inch to determine the TPI.

- Measure the distance between threads in millimeters to determine the thread pitch.

- Using the OD measured in inches and the TPI, assemble the standard version of your measurement. It should look like: inch OD-TPI . (Example: 1/4"-28)

- Using the OD measured in millimeters and the thread pitch, assemble the metric version of your measurement. It should look like: M OD x thread pitch . (Example: M4 x 0.7)

- Take both versions of these measurements to a local hardware store; you can then identify the fasteners with the closest measurements to yours.

- For more accurate measurements, consider investing in inch and metric thread gauges. These small tools look like pocket knives and hold fans of blades with different sized notches. The notches correspond to thread sizes, which are marked on the blade. Press the threads of your part against the different blades until you find the blade that nestles perfectly on the threads. This will not only tell you whether your part is an inch or metric part, but it will also narrow down the exact TPI or thread pitch.

- Remember not to mix standard and metric fasteners. They are designed to work with appropriately-mating parts; if you mix a standard bolt with a metric nut, the threads may not hold correctly. This can cause damage to your application and could be a safety concern.

Measurement Charts

Size charts for nuts and bolts can cover a variety of measurements. Ours cover common nut and bolt sizes for fasteners with ODs up to 1" and 25mm. We include the following essential measurements:

- Thread size: This indicates the full size name. For inch fasteners, this is the OD followed by the TPI. For metric fasteners, an "M" is followed by the OD, which is then followed by the thread pitch.

- Outside diameter (OD): This is the basic actual measurement that correlates with the thread size.

- TPI/Thread Pitch: The standard chart lists the correlating TPI, while the metric chart lists the correlating thread pitch.

- Coarse/Fine Thread Designation: The standard chart uses the "UN" acronymns explained above, while the metric chart uses the words "coarse" and "fine" in accordance with ISO's designations.

Other Measurements for Common Nut and Bolt Types

While the outside diameter and TPI/thread pitch are the essential measurements for every type of nut or bolt, different types of fasteners have other unique measurements that are important to know.

Nuts

Most

nuts have three main measurements beyond the OD and TPI/thread pitch:

A: Face-to-face width; B: Corner-to-corner width; C: Thickness

Exceptions to this are

wing nuts, which are decidedly different shapes than nuts with hex shapes like

hex nuts,

coupling nuts,

lock nuts, and

jam nuts.

Wing Nut

A: Wing Span; B: Total Body Height; C: Distance Between Wings; D: Overall Diameter

Bolts

There are a wide variety of bolt types with unique features and profiles that require unique measurement callouts.

Lifting Eye Bolts

A: Shank Diameter; B: Shank Length; C: Thread Length; D: Inside Diameter; E: Outside Diameter

Step Bolts

A: Diameter of Head; B: Square Width; C: Head Height; D: Square Depth; E: Diameter of Full Size Body; F: Length

Have Questions About Part Sizes, Availability, or Custom Options?

Contact Huyett's friendly, knowledgeable Sales team today at

sales@huyett.com.