Precision Balls

Precision Balls

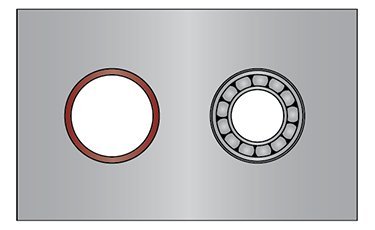

Precision balls - also referred to as loose ball bearings or precision metal balls - are precision ground spheres used as rolling elements in precision

ball bearing assemblies, in which the balls are sandwiched between two metal races to allow for spinning. The surface is fine-finished and through-hardened for handling high load capacities.

Precision balls are used in a wide range of applications ranging from ball bearing assemblies and precision valves to free wheel mechanisms and kinematic mounts. Specific examples include skateboard wheels, fan motors, fishing reels, medical or food processing equipment, or other applications in which the function depends on frictionless spinning.

Application Considerations

Precision balls are essential components in a ball bearing assembly. Here are a few key points to consider before purchasing these components for your application.

- Load Requirements: The force of the application load should influence the material, grade, specification, and size of the balls and ball bearings. Most ball bearings are suited for low load-bearing scenarios.

- Rotational Speed: Ball bearings usually facilitate high-speed, frictionless rotation; it's important to know the speed that the balls will need to support in the application.

- Ball Bearing Compatibility: Ensure that the sizing and tolerances are compatible with the bearing you intend to use.

- Material Requirements: The precision metal balls need to support the ball bearings, which should be harder material than the mating shaft. The material should also exhibit the proper wear resistance, corrosion resistance, and any other resistant properties necessary to ensure optimal performance.

- Lubrication: Some ball bearing applications require lubrication, and at times the need is very specific. Make sure you select the proper lubrication and that the ball and bearing material will hold up under it.

Benefits

Precision metal balls offer three key benefits for your application:

- High Precision: Unsurprisingly, precision balls are a precision product. There is virtually no surface roughness so defects don't interrupt the bearing rotation, which helps maintain speed and reduces the risk of wear and tear on the bearing. This feature also makes the balls well suited for uses outside of ball bearings, like precise calibration, surgical tools, and sealing mechanisms.

- Cost Efficient: Precision balls are economical elements, especially considering their precise nature. They are available for purchase at Huyett in a wide range of sizes low minimum quantities.

- Versatile: Not only are the balls useful in a wide range of applications - whether present in ball bearings or not - they are also made versatile by their material, specification, sizing, and material grade variations.

Precision Ball Materials

Precision steel balls are offered in a range of materials, but Huyett's most popular choices are chrome alloy and stainless steel.

- Chrome Alloy: Also labeled "chrome steel," chrome alloy is a low-carbon steel fortified with chromium and molybdenum. This combination offers better strength, hardenability, toughness, and corrosion resistance than plain low-carbon steel. Huyett offers chrome alloy balls in ASTM A-295 and DIN5401 specifications.

- Stainless Steel: Stainless steel balls offer excellent resistance to corrosion and temperature fluctuation while maintaining strength, cleanliness, and hardenability. Huyett offers stainless steel balls in material grades 302, 316, 420, and 440.

Huyett also offers limited, special-order options for these components in carbon steel, Buna-N, and brass.

What Are Precision Ball Bearings Used For?

Precision steel balls are versatile and can be used in a variety of ways, but one of their most popular uses are within precision ball bearings, where they perform an essential function.

Precision ball bearings are used to facilitate rotational speed between a shaft and a bore. The hollow bearing consists of two metal circles (or races) that house the precision steel balls in between them. A shaft runs through the hollow bearing center (touching the inner race), and the outer race contacts the mating bore. The metal balls allow either the shaft or the bore to rotate without friction.