Turnbuckles

What is a Turnbuckle?

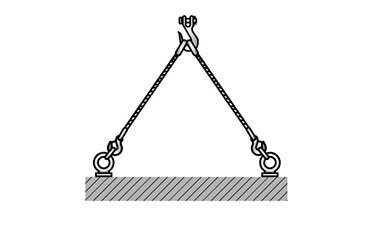

A turnbuckle, a versatile rigging component, is a 3-piece devise used for adjusting slack and tension in terminating chains, ropes, and ties in rigging, hauling, and lifting applications. It consists of two threaded ends connected by a central body. The threaded ends feature a variety of end fittings to suit different application needs.

Turnbuckles connect the end of one chain, rope or tie to a rigging assembly by hooking the two components to the turnbuckle end fittings and threading those ends towards each other. This creates tension between the two parts.

Application Considerations

Turnbuckles are a key component of many rigging assemblies. Here is a list of some of the most common application factors to consider when choosing your hardware.

- Load Requirements: Evaluate the kind of force and tension your rigging application will put on the turnbuckle, which will feature a respective Working Load Limit (WLL) telling you if it can support the load.

- Tie Length Requirements: Know how long your rope, chain, or ties will need to be when the turnbuckle is in position. Will your hardware extend to the desired range? Will it leave slack in its shortest state? The take up length is an essential consideration for your hardware.

- Connection Point: Think about the components that will attach to your turnbuckle. What kind of connection point do they require? This will influence the type of end fitting (hook, eye, stub, jaw, etc.) you choose for your hardware.

- Regulations: This is an especially important consideration. Carefully evaluate your application to determine if it needs to comply with any industry regulations or guidelines to ensure a safe working environment.

- Environmental Elements: Will your turnbuckle be exposed to environmental elements like water, temperature fluctuations, chemicals, or other potentially damaging issues? In particular, will it be exposed to saltwater, which could put it at risk of galling? The component's material and finish will largely impact its corrosion resistance and should be an essential factor in your choice of hardware.

Benefits

There are several benefits of using these versatile fastening components in rigging devices. They are:

- Versatility: A turnbuckle's take up length allows it to adjust to a range of application needs, while the variety of end fitting combinations allows it to attach to different types of mating rigging components.

- Reusability: As long as the hardware is used properly, cared for, and remains undamaged, it is a reusable and sturdy rigging investment.

- Easy Installation: A turnbuckle offers a simple installation process that makes it easy to use in different application environments, even in awkward or constrained fits.

- Customizable: There are many ways to combine a turnbuckle body with different end fittings to customize your rigging connection, as long as the threads of both parts align.

Product Line

Huyett offers a wide range of turnbuckles from our

Aztec Lifting Hardware line. Shop our full range of lifting and rigging products, including

chains and

chain hardware,

lifting eye nuts,

hooks, and more.

Different Types of End Fittings

Turnbuckles are composed of a body and two threaded studs. These three components detach from and attach to each other to form different varieties of turnbuckles. Huyett offers the following components so you have multiple options to create the perfect combination for your application:

- Turnbuckle Body: An open metal frame with two open threaded ends set at a specific distance apart to accept threaded studs.

- Eye End: A threaded stud with a closed eye at the unthreaded end.

- Hook End: A threaded stud with a hook at the unthreaded end.

- Jaw End: A threaded stud with an open jaw and holes for a bolt pin or clevis pin at the unthreaded end.

- Stub End: A threaded stud with plain unthreaded rod end.

Huyett also offers complete turnbuckle combinations, including:

How to Install and Secure Turnbuckles

To install a turnbuckle, follow these steps:

- Unthread the end fittings until they extend almost completely out, leaving only a small portion threaded in the body.

- Connect the end fittings to their respective rigging component.

- Rotate the turnbuckle body, not the end fittings, to tighten the entire component. If the end fittings rotate, the connecting cable or tie may twist and compromise the application.