Lock Nuts

Introduction to Lock Nuts

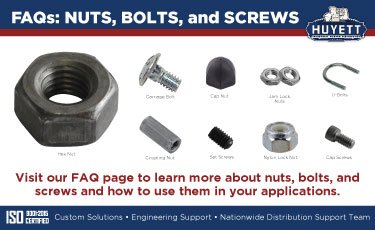

Lock nuts are a Huyett product range available in several types, materials, and sizes – search the full selection to find the right style for your application needs. Also known as a self lock nut, locking nut, prevailing torque nut, or self-locking nut, these fasteners offer increased resistance to loosening by using either metal or additional material to elevate its locking action. This trait makes them essential hardware for a multitude of applications.

Huyett offers a wide range of lock nuts, each with their own unique characteristics to aid in different application settings.

Application Considerations

Lock nuts are fasteners with unique designs and purposes. There are a few key points to consider about your self lock nut application that will differ from the use considerations of other types of nuts:

- Vibration: It is important to understand the amount of vibration your application will generate and how resistant your choice of lock nut is to it. This will help you determine the strength of your desired locking function and if you need a light-duty, heavy-duty, or specific style of nut.

- Temperature Exposure: Many of these nuts have nylon inserts to form the locking mechanism, but these will not withstand temperatures above 250⁰. Your application's temperature exposure may help you decide between nylon lock nuts and metal lock nuts.

- Corrosive Elements: Your application may be exposed to either natural elements like water, temperature fluctuations, sun, and debris; or lubricative/chemical elements like oil or cleaning agents. Your self lock nut may need to resist these elements, which will help you choose the correct material (typically carbon steel or stainless steel) or whether your nut should have a nylon insert.

Benefits

There are several benefits of working with lock nuts over standard nuts, including the following:

- Resistance to Loosening: The most obvious benefit, these nuts feature extra vibration resistance, making them a great choice for automotive, transportation, and other high-motion applications.

- Simple Installation: Most nuts do not require special tools for installation and are installed with a common wrench or even by hand.

- Cost Efficiency: These nuts are a more durable and reliable option for applications that cause traditional nuts to wear out earlier, which in turn means your application will require less maintenance and part replacements.

- Safety: Self lock nuts may reduce the risk of structural issues in high-motion settings.

- Materials and Finishes: Along with the corrosion resistance and characteristics offered by nylon and carbon or stainless steel options, self locking nuts are available in different finishes that increase that resistance.

How Does A Lock Nut Work?

Self lock nuts work by using metal or nylon to increase the friction, connection, or surface area between the nut and its mating component. Some nuts use nylon to deform around the mating thread to keep it in place, resisting torque, shock, and vibration. Other lock nuts work by using metal to create a locking friction or to bite into mating material with teeth.

Lock nuts are used in a wide range of applications like construction, automotive, plumbing, transportation, and even furniture. In many of these environments, the nuts are used to keep structural elements from disconnecting during motion.

Lock Nut vs. Hex Nut: What Is The Difference?

The difference between a lock nut and a hex (or normal) nut is simple: a hex nut provides basic holding power by screwing onto a threaded mating component (like a bolt); a self lock nut also connects to a threaded mating component, but it provides better holding power through one of the following self-locking designs:

- Nylon inserts that deform around the mating threads

- Surface area tension between mating nuts jammed together

- Metal teeth that bite into the mating material

- Wedge design that interlocks elements of a multi-piece nut when subjected to vibration or shock

While locking nuts and hex nuts look similar and perform the same kind of function, hex nuts are better suited for applications that do not need to resist significant movement.

Types of Lock Nuts

Huyett offers a range of self lock nuts that provide unique benefits based on their design.

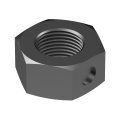

- Jam Lock Nut: Thin hex nuts that are used in pairs to tighten against each other and "jam" into place

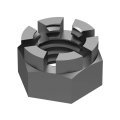

- K-Lock Nut: Hex nut with a connected toothed washer to bite into mating components

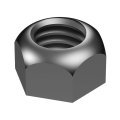

- Nylon Lock Nut: A hex nut with a nylon insert to grasp onto mating threads

- Wedge Lock Nut: Multi-piece Sherex Disc-Lock® design that interlocks into place during vibration

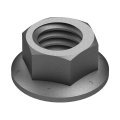

- Flange Lock Nut and Wing Nut designs available on special order