Dowel Pins

Metal Dowel Pins

Dowel pins are short cylindrical rods that are made up of either metal, plastic, or wood and are used to align or join two or more components in machinery, construction, and furniture making. They have many uses, such as aligning machine components during assembly for consistent results, joining stone and concrete in masonry, and providing precision holes for mating fasteners.

Dowel pins are used in a variety of applications, from the automotive and aerospace industry to medical equipment and electronics. Their main purpose is to provide precision connections, which is why they often appear in critical components.

Huyett provides dowel pins in common materials like steel, brass, and aluminum and offer a wide selection of sizes, including the prevailing standard for imperial (ASME B18.8.2) and metric (DIN) sizes.

What to Consider When Choosing Your Dowel Pins

Because dowel pins are designed for precision alignment uses, there are several specific points to consider about your application before choosing your pin.

- Connection Type: Will your dowel pin serve as a temporary or permanent solution? Your pin may need to protrude from the application or possess a feature that allows for easy removal (like internal threads).

- Mating Fastener Requirements: Does your application require additional fasteners - like nuts and bolts - to aid the connection? If so, your dowel pin needs a hollow center.

- Gas or Liquid Presence: If gas or liquid is present in your connection, you may need to incorporate a venting mechanism into your application. The mating dowel pin will need to support that need within its design.

- Motion/Forces/Pressure/etc.: Will your application exert shock, shear force, or other types of motion? If so, your dowel pin will need to withstand that motion - consider the pin's material along with its load bearing capacity, toughness, and other mechanical properties.

- Environmental Elements: If your application will be exposed to natural or chemical elements (water, temperature fluctuations, lubrication, dirt/debris, etc.), it is important to consider your dowel pin's material and finish to ensure the proper corrosion and wear resistance.

Benefits of Using Dowel Pins

Dowel pins are versatile and simple pins that offer several key benefits, especially when precision is paramount. Here are some of the most prominent advantages that these fasteners offer:

- Precise Tolerances: These pins are hardened to precise dimensions, making them ideal for machinery, furniture, electronics, etc. that rely on critical alignment for peak performance.

- Durability: Metal pins hold their shape and resist deformation, even after repeated use. They also possess good shear strength and do not chip easily.

- Ease of Use: These fasteners are simple to install with an arbor press and easy to remove with pliers (if the end protrudes from the component) or a punch and a hammer (if the pin is flush with the mating surface). They also work as a stand-alone fastener, although some designs allow for a mating fastener to pass through the hollow center.

- Lateral Movement Prevention: These pins add shear strength to their mating components, preventing lateral movement.

Types of Dowel Pins

Huyett offers a selection of dowel pins that accommodate a wide variety of application requirements:

- Standard Dowel Pin: Solid pin with a smooth surface; available in ASME B18.8.2, DIN, and mil-spec specifications. Ideal for precision alignment and connections with basic requirements.

- Flat Vent Dowel Pin: Solid pin with a small flat surface to allow for gas and liquid to vent through the mating hole and chamfered ends to ease installation. Internal threads provide an easy removal mechanism.

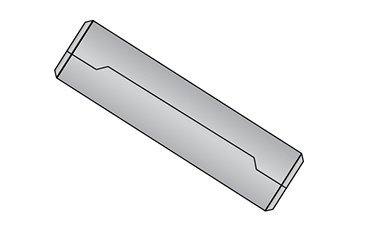

- Grooved Dowel Pin: Solid pin with a grooved surface that compresses upon installation to create a self-locking tension. Ideal for applications like pivots, levers, and locking devices.

- Ground Hollow Dowel Pin (or alignment dowel): Hollow rolled pin with chamfered end to ease installation. Hollow center makes it ideal for applications that require additional fasteners (like a bolt).

- Pullout Dowel Pin: Solid pin with an internally threaded hole on one end to allow a slide hammer to remove the pin. Ideal for blind applications or situations where the pin needs to be removed from the same end as it was installed.

Dowel Pin Sizes

Dowel pins are available in a range of sizes, including standard specifications, inch and metric sizes, and custom sizes. Huyett offers a variety of options in the following categories:

- ASME B18.8.2 Hardened Ground Standard Dowel Pins: These pins are intended for general use, but feature a round head with a chamfered end and specific, tight tolerances to align with the ASME standard; outside pin diameters range from 1/4th in. - 1 1/4th in.

- DIN 7 Dowel Pin: Huyett offers these oversized pins in Tolerance Zone m6, meaning they possess two rounded ends and a pin diameter range of 1mm - 32mm and varying min./max. tolerances based on the pin size.

- DIN 6325 Dowel Pin: These pins feature pin diameters from 1mm - 20mm (exceptions are at the discretion of the customer and producer) and a rounded head with a chamfered end.

- Metric Sizes: Huyett offers standard, flat vent, and ground hollow pins in a variety of metric sizes.

- Inch Sizes: Huyett offers standard, flat vent, grooved, and pullout pins in a variety of inch sizes.

For custom size inquiries,

contact our Special Quotes Team.

How to Measure Dowel Pins

Each type of dowel pin will have specific measurements that pertain to their design. For example, pullout pins will have a thread size and diameter and ground hollow pins will have a mating bolt size. However, with the exception of the DIN 7 pin, each dowel pin has two key measurements to know.

Watch our Sales expert explain how to capture these measurements:

Watch here to learn how to specifically measure DIN 7 dowel pins:

Dowel Pin Materials and Finishes

The material and finish of your pin will affect how it performs in your application by influencing the pin's strength, its corrosion resistance, and its durability within its environment. For instance, a stainless steel dowel pin will be highly resistant to rust; this can be enhanced by the addition of a passivated finish.

Huyett offers our selection of dowel pins in popular materials and finishes to help you choose the right combination for your needs:

- Standard Pin: 300/400 series stainless steel, alloy steel, alloy/carbon steel, aluminum, brass, and carbon steel with black oxide, passivated, plain, and zinc clear finishing options

- Flat Vent Pin: Alloy steel with a plain finish

- Grooved Pin: Alloy steel with a plain finish

- Ground Hollow Pin: Low carbon steel with a plain finish

- Pullout Pin: 300 series stainless steel and alloy steel with a plain finish

For a more in-depth look at material and finishing characteristics and mechanical properties of metal, take a look at the following Huyett guides:

- What Is Key Stock Material?

- Mechanical Properties of Metal: An Introduction

- Types of Metal Finishes: An Introduction