Retaining Rings

Retaining Rings

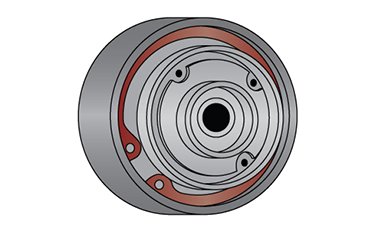

Retaining rings are fasteners that are typically installed into a shaft groove or housing groove, creating a shoulder that holds components in place by exerting radial force by either pressing inwards or outwards on their mating component. They are often used instead of other fasteners such as bolts or pins to reduce the need for threading and tapping.

A retaining ring's primary purposes are to reduce the mating component's movement by blocking the axial motion with its shoulder and/or to bear the load of that component. Application uses range from conveyor belts, hub assemblies, and agricultural equipment to household appliances, all of which may require retaining rings to function in a light or heavy-duty environment.

What To Consider When Choosing Retaining Rings

Retaining rings may look simple, but they support essential functions that require them to hold up under force. Considering this, there are several important factors to think about when choosing the right ring:

Shaft or Bore Size: This includes the diameter, the depth of the bore or shaft groove that the ring will occupy, and the groove size (the height of the groove); this will help you determine the appropriate ring size. As a general rule of thumb, external retaining rings will be smaller than their mating shaft, while internal retaining rings will be larger than their mating housing - this ensures the ring delivers proper tension.

Thrust Load: This refers to the axial force that the mating component will exert on the ring (if the application uses axial force); it will help you determine the appropriate thrust load capacity that your ring needs to possess.

Rotational Speed: Sometimes the application will exert rotational force; in this case, it's important to know the speed of that force so you can choose the correct ring diameter, as the ring will need to stay attached during rotation.

Shaft or Bore Design/Placement: The shaft or bore design or placement will affect whether the ring needs to be installed from the top/bottom or from the side; this will help you determine if you need an axial retaining ring (designed to install from the top or bottom) or a radial retaining ring (designed to install from the side).

Application Environment: Will the application be exposed to natural elements like rain, temperature fluctuation, sun damage, or dirt/debris? Will it be exposed to lubrication or chemicals? The environment will help you choose the material and finish of your ring.

Retaining Ring Benefits

There are several reasons to choose a retaining ring over a different type of fastener. Here are a few common benefits that influence that choice:

Cost Efficiency: Retaining rings are an economical choice, especially considering that most types are reusable (do not reuse retaining rings that deform after use).

Simple Installation and Removal: In most cases, these fasteners can be installed either axially or radially with retaining ring pliers that attach to the lug holes, household pliers, or even screwdrivers (commonly used to install external spiral rings).

Simple Design: These fasteners feature a straightforward, lightweight design that does not weigh down your application or take up excess space.

Size and Style Options: Retaining rings are available at Huyett in a wide variety of sizes and styles to accommodate different applications.

Materials and Finishes: Huyett offers different types of retaining rings in a wide range of materials and finishes so you can choose a ring that will withstand your application's environment.

Retaining Ring Product Lines

Huyett offers retaining rings from trusted suppliers like

Rotor Clip®. Choose from a variety of styles, from common (like internal external rings) to hard-to-find types (like e-clips and c-form rings).

Difference Between External (or snap) Rings and Internal Rings

The main difference between an external retaining ring (or snap ring) and an internal retaining ring (or housing ring) is simple - it is based on where they are placed in an application.

- An external ring fits the outside of a shaft and exert inwards force against the shaft; they can be installed either radially or axially.

- An internal ring fits inside a bore and exert outwards force against the housing; they can only be installed axially.

The two types of rings have a slightly different design which may be hard to spot at first, but it largely depends on the lug design.

- A snap ring's lug holes protrude outwards from the ring because that leaves the inside of the ring smooth; the lug holes do not interfere with the ring embracing the shaft.

- A housing ring's lug holes face inwards towards the internal diameter of the ring because that leaves the outside of the ring smooth; the lug holes do not interfere with the external circle pressing against the housing.

These are the most common types of retaining rings. However, there are many other types to accommodate different application needs.

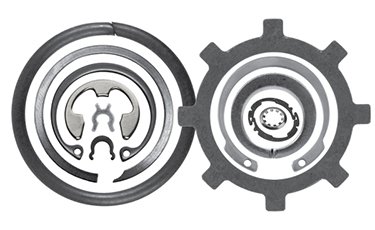

Retaining Ring Types

Each type of retaining ring serves a unique purpose in an application. This list provides the range of ring types that Huyett offers to help you find the right fastener to fit your needs:

- C-Form: Wire-formed; meant for groove-less shafts with low thrust bearing loads.

- Constant Section: 360⁰ circle with no lug holes; meant for low thrust bearing loads.

- Crescent: Wide gap with no lug holes; meant for low thrust bearing loads in need of good clearance.

- Crimp: 360⁰ circle with no lug holes and a small gap; meant to reduce gap upon installation.

- E-Clip: Three-pronged with wide gap; good for larger retaining areas and higher thrust bearing loads.

- Grip: Stamped with wide gap and no lug holes; features self-locking design with or without a groove.

- Hog: Wide gap with pointed ends; good for light applications like upholstery, sealing bags, and plastic.

- Interlocking: Two interlocking semicircles; good for highspeed rotation.

- Poodle: Wide gap with wide side shoulders; offer extra retention against the mating component.

- Pronged Lock: Variation of a bowed e-clip; good for moving parts.

- Push-On: Teethed internal or external circle; features self-locking design for light-duty applications.

- Rectangular Wire: Slanted gap with no lug holes and a rectangular cross section; provides a larger shoulder.

- Round Wire: Open gap with straight edge; designed for round grooves in lighter applications.

- Spiral: Coiled flat wire with no gap; easy to install and remove and good for 360⁰ contact.

- Square Wire: Square material; offers more shoulder strength than round wire.

- X-Ring: X-shaped design; crimps shut with pliers for 360⁰ contact.

Retaining Ring Tools

Retaining ring tools are designed to help install and remove different types of rings. There are three types of tools that Huyett offers:

- Snap Ring Pliers: These are specific pliers that install and remove internal and external rings with tips that fit the lug holes; there are different types of plier tips available depending on the type of ring in use.

- Retaining Ring Applicators: Applicators help install unique rings like e-clips, c-clips, and poodle clips by snapping them into place.

- Retaining Ring Dispensers: These tools hold stacks of retaining rings that can then be grabbed by an applicator; this is quicker and more efficient than manually loading the applicator.