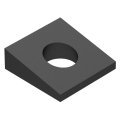

Beveled Washers

Maximize Precision and Stability with High-Quality Beveled Washers

Beveled washers are designed to address the unique challenge of joining non-parallel surfaces. Unlike flat washers, beveled washers feature a sloped side that helps orient and secure fasteners when surfaces are not aligned. This wedge-shaped design allows for a stable and tight fit where the bolted joint remains secure even under varying loads. They are often used to wedge under bolts and ensure they are installed at the correct angles. These washers are essential in complex structures like vehicles, buildings, and bridges, where precision and durability are critical.

The primary role of beveled washers is to provide a flat bearing surface for bolt heads on non-parallel surfaces. This function is vital in preventing bolt loosening and component damage, especially in structures subjected to heavy loads and vibrations. Square beveled washers offer added stability and load distribution due to their shape. They are not only functional but also versatile, catering to a wide range of applications in construction and manufacturing, where alignment and load-bearing capacity are paramount.

- Precision Alignment: These washers ensure proper alignment and tightening of bolts on non-parallel surfaces.

- Load Distribution: They evenly distribute loads to prevent damage and enhance joint stability.

- Corrosion Resistance: Huyett offers square beveled washers in iron and hardened steel with zinc and hot-dipped galvanized finishes for additional corrosion resistance.

- Related Products: Shop Huyett’s selection of flat washers, bonded sealing washers, lock washers, and more.

How to Determine the Angle of a Square Beveled Washer

The angle is determined by the thickness at the washer's thinnest and thickest points. It is engineered to match up with the flange of an I-beam and form a parallel bearing surface.

Beveled Washers vs. Flat Washers

The main difference between these two types of washers is the shape; flat washers are not angled. Functionally, they both distribute the load of the bolt to reduce the stress on the mating surface. However, if the surface is uneven and the bolt will not properly align, the application may require a beveled washer.